OUR PRODUCTION

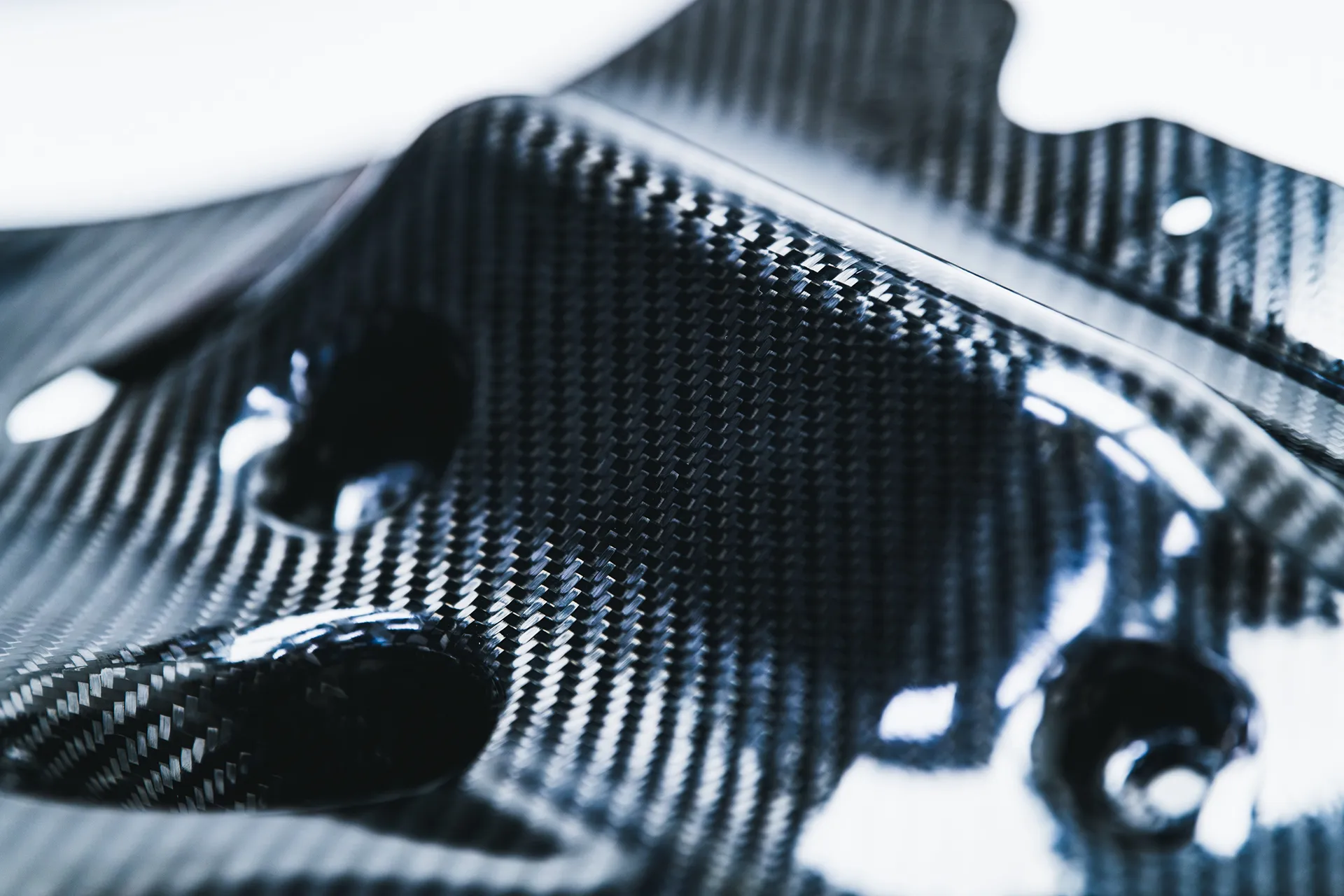

We help race teams win. We supply components that meet the highest demands of our customers and withstand the extreme conditions of race tracks.

WE PRODUCE ORIGINAL

PARTS AND SERIES

We specialise in the production of original carbon components for WRC, WEC, GT3 and Formula 1 race cars. Sébastien Loeb, Jenson Button and Mick Schumacher, for example, have driven our parts. We are also involved in small-scale series production and our parts are significantly represented in regular use on the Praga Bohema supercar. All our products are the result of painstaking handwork.

WE’RE NOT JUST A SUPPLIER.

WE ARE A PARTNER

We understand the needs and wishes of our customers because motorsport is our passion.

We check every order carefully and if we find any discrepancies, we immediately communicate with the customer and together we find the best solution.

Thanks to our unique customer portal, you can keep track of the current shipment schedule, which is linked in real time to our production system.

We place emphasis on transparency and communication. With us, you always know what we are working on and when you can expect delivery.

We rely on state-of-the-art technology, precise processing and speed. We take special care with every part, because in motorsport, the details decide the winner of a race.

WHERE YOU CAN FIND OUR PARTS

Formule 1

We specialise in handcrafting genuine carbon components for Formula 1. F1 represents the absolute pinnacle of motorsport, not only in terms of on-track performance and massive spectatorship, but also in terms of advanced manufacturing technology. Our inclusion as a supplier is a testament to the technological maturity and precision with which we produce parts that meet the highest standards in the industry.

World Rally Championship

Three automotive brands participate in the World Rally Championship at the highest level. And we produce carbon parts for all of them. During the WRC, our parts are exposed to extreme conditions. From crashing into snow barriers in Sweden, to being battered by rocks on long gravel tests in Greece, to extreme temperatures on asphalt stages. Our parts can also be found on almost all active models in the Rally2 category.

CIRCUIT RACING

Circuit racing requires precision processed parts. We produce components primarily for the top racing teams that participate in the WEC championship with the season’s main race at Le Mans. We are also a major supplier for several GT3 cars.

Automotive

In addition to motorsport, we also focus on the automotive sector. We are a major supplier of the new Praga Bohema supercar. Series production of the first cars has already started. The plan is to produce a total of 89 units.

DEFENCE INDUSTRY

Our experience extends to the defence industry. We are involved in the supply of components for radar technology and armoured vehicles. However, as this is classified information, we cannot give more details.

LOOKING FOR QUALITY AND SPEED? YOU CAN RELY ON OUR PARTS.

WHAT OUR SATISFIED CUSTOMERS SAY ABOUT US

WE TRAIN EVERY NEWCOMER

We want new team members to settle in quickly, so we give them our full attention! During their first month with the company, each employee goes through an onboarding program to get to know the entire production process and key people at RaceX. Our goal is for people to feel comfortable with us and get to know us as well as we get to know them.

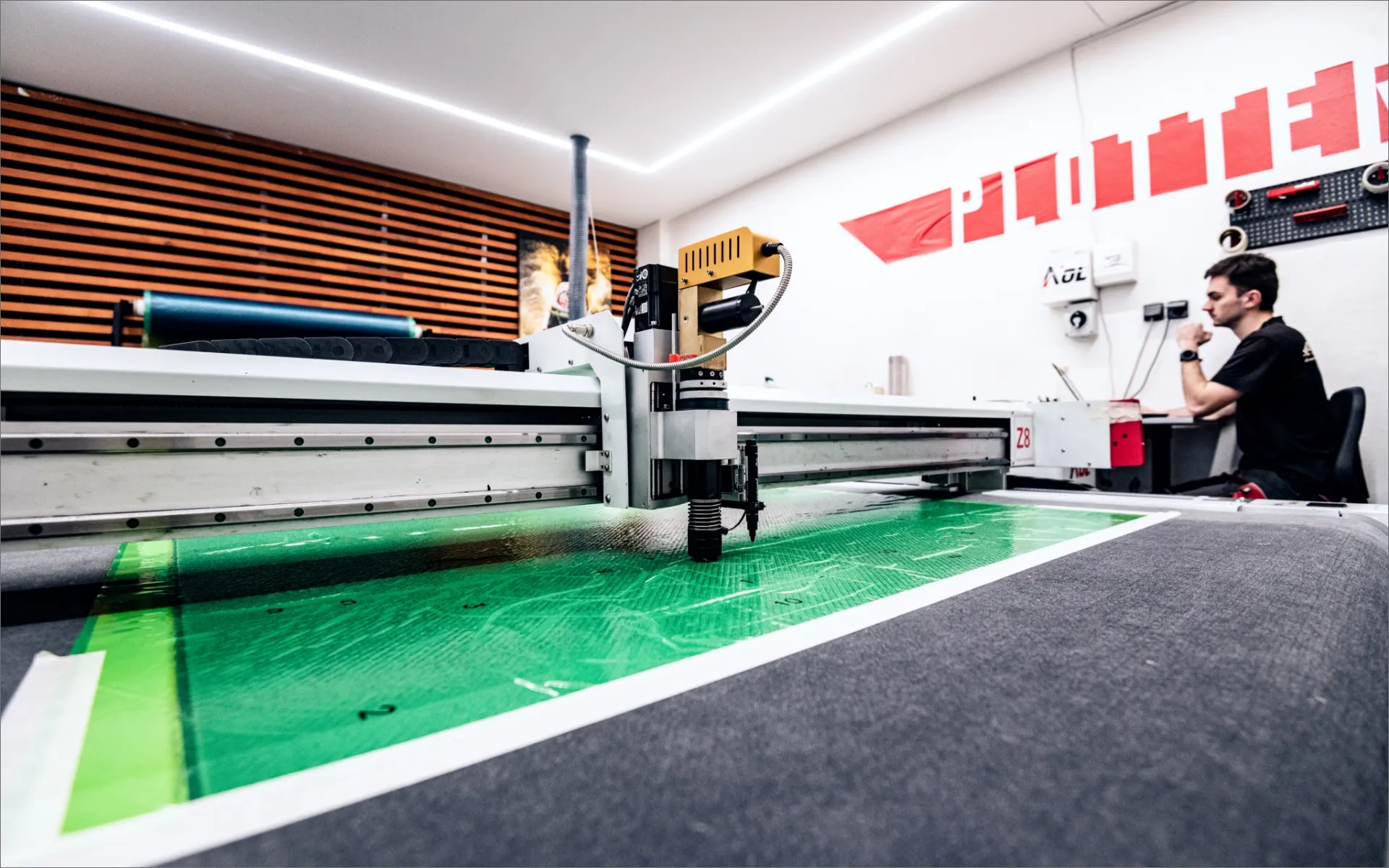

TECHNOLOGY EQUIPMENT

AUTOCLAVE

Ø1,5m x 4m (250°C – 9 bar)

AUTOCLAVE 2

Ø 2,3m x 5m (250°C – 8,5 bar)

Cutter 1

AOL-1625Z8 2,5m x 1,6m

Cutter 2

Zünd G3 5m x 1,8m

Software

3DEXPIRIENCE CATIA, PolyWorks

SEVEN-AXIS MEASURING ARM

- Nikon MCAxS25 PLUS – measuring range 2.5m

- NIKON H120x laser scanner

PRODUCTION STEP BY STEP

Our standard production process consists of 10 steps. If we are making a mould for a new part, the whole process involves 3 extra steps. Each step of production is carefully planned and executed using state-of-the-art processes.

MOULD PREPARATION

PRODUCTION OF PARTS

From this step on, the production of the mould and the part is identical.

In the clean room, we lay the individual layers of prepreg in the moulds.

Finishing includes bonding in jigs, cleaning and final finishing to ensure parts meet all quality requirements.

We inspect each part according to the drawings in the tablets. 3D scanning is done for all moulds and new parts, for others according to customer requirements.

We mark the finished parts with the required label and ship them to the customers in the way they choose.

LOOKING FOR QUALITY AND SPEED? YOU CAN RELY ON OUR PARTS

Are you interested in our high-end carbon parts or would you like more information about our services? Contact us to find out how we can help you.